Welcome to our Frequently Asked Questions section.

Click below on your question to find the answer. If you can't find the answer, you can send us an e-mail

Click below on your question to find the answer. If you can't find the answer, you can send us an e-mail

- What types of blank apparel can you print on?

- Do you offer garment distressing and knicking?

- What types of effects can you create?

- How much does custom screen printing cost?

- How much is custom design?

- How much is shipping?

- Do I have to pay a sales tax?

- What is the setup cost?

- Where are you located?

- How can I contact you guys?

- Do you offer garment splattering?

- Do you offer full body printing?

- What file formats should I use?

- What is the turn around time?

-

What types of blank apparel can you print on?We have custom garment embellishing for hundreds of different types of blank apparel. We like to offer customers a variety of blank apparel to choose from based on their needs. We offer screen printing and embroidery on brands like American Apparel, Alternative Apparel, Gildan, Jerseez, Hanes, etc. We also take customer suggestions. Back to Top

-

Do you offer garment distressing and knicking?Yes we offer garment distressing and knicking. See out specialty services page to see some examples. Back to Top

-

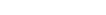

What types of effects can you create?

A.) Not only can you achieve the worn, distressed-looking prints that are currently popular, but you can also provide them with a very soft hand. In this sample, a new, soft-feeling plastisol base called Chino was printed through 230-thread/in. mesh without flashing and without an underprint.

B.) In the past, printers could only produce the type of soft-handed print shown here on light-colored or white garments. Halftones were usually necessary in these designs to help soften the feel of the print. The halftone image shown here was printed using an ink made with Chino Base, through 305-thread/in. mesh, and without flashing.

A.) Here, Chino ink was printed without an underprint on a dark garment with fine-mesh screens. The softness and opacity have been dialed in to give the desired finished appearance on the black fabric.

B.) This shirt features a print produced using halftones and screens with very high mesh counts. The resulting design simulates the unique and very popular distressed look typically created by printing entirely through the fabric of the garment from the inside, a technique sometimes referred to as reverse discharge printing.

The print shown in this photo was created with thickened soft-density inks printed through 83-thread/in. screens with stencils 250 microns thick. A split fountain was used for the gray portion of the image (very light gray, medium gray, and black inks were put onto the same screen and printed in the same pass of the squeegee). The squeegee blended the inks together for a very nice gradation of colors. The thick viscosity of the soft-density inks helped create a very stable and consistent blend. The properties of these specialty inks prevent the colors from gradually becoming over-blended and muddy.

A.) Shatter Base is a new plastisol that was developed to easily crack apart. In this print, white ink made with Shatter Base was printed through an 86-thread/in. mesh, flashed, and printed a second time through a 110-thread/in. mesh to build up the proper amount of ink and produce a smooth surface. The print was cured with a moderate amount of extra heat. The combination of proper ink deposit and sufficient heat produce a graphic that feels brittle and cracks apart fairly easily.

B.) To produce this graphic, the squeegee blade was replaced with a specially modified wallpaper brush. These wood-handled brushes are available from most hardware stores and can be easily cut down to fit into most standard squeegee holders. Soft-hand inks were then printed with the brushes through 305-thread/in. screens. This technique creates an interesting distres

A.) The crackle texture shown here was created by printing a large number of simple squares of opaque white ink onto black fabric. The printed pieces were under-cured to different degrees, stretched varying amounts, and then washed repeatedly until they cracked apart. The best results were then scanned into a graphics program and adjusted slightly. The scanned image was then placed into the design. The graphic was printed with a soft-density white ink through a 200-thread/in. screen. The ink was chosen for its opacity and very soft feel. Both properties were enhanced by a small amount of puff additive.

B.) The halftones used to produce this print were created by scanning ink that was actually printed through a garment from the inside. The image was manipulated in Photoshop and then printed directly onto other garments. New plastisol formulations help create additional softness in the graphic and make the simulation of reverse discharge printing appear more realistic.

A.) A gray water-based ink formulated for cracking was printed through a screen with a low mesh count, flashed, and then overprinted again to build a sufficient ink-film thickness. The cured print cracks apart easily when it's bent or lightly stretched.

B.) A somewhat more difficult technique is shown in this photo. In this print, a crackle ink was printed on top of a standard plastisol. The base layer of plastisol adds a nice contrasting color to the print, but it also requires more vigorous stretching of the print in order to achieve the cracking effect.

A.) In this graphic, a thick Blister Base foundation was printed, flashed, and covered with two layers of suede ink. The last layer of suede was not flashed. A layer of process-black ink (you can substitute another very thin black ink) was then printed last. This creates a very soft, realistic suede feel.

B.) Here, a very thick layer of Blister Base is covered with a moderately thick layer of Thermoline clear. Running the print slowly through a very hot dryer creates a rock-like surface texture.

A.) Here, a soft-density ink was used for the outline and printed with a wallpaper-brush squeegee through an 86-thread/in. mesh with a stencils 250 microns thick. The brush created the textured, worn-looking outline. A soft-hand Chino ink created the fill color. You can also print a soft-density ink through a screen with a low mesh count and standard stencil to fill the outlined letters.

B.) Wrinkled platen tape was applied to the printing platens to produce this effect. The print takes on the texture of the platen. Using different types of inks will yield a variety of different effects, depending on the texture used. This is another technique that gives a slightly different finished appearance to each print. You can print any type of standard graphic onto a textured board or platen to create a unique print, and a wide variety of textural materials can be applied to the platens before printing.

A.) This graphic was designed to look like a high-density print that became distressed and worn out over time. The first few colors in the design were printed through screens with low mesh counts and thick stencils—both a necessity when working with high-density inks. Additional soft-density colors were then printed through 230- and even 305-thread/in. mesh over the uneven, raised surface. You can experiment with texture in the artwork and vary your printing technique to achieve a range of different effects.

B.) Creating this design involved printing a very thick layer of a plastisol product called Blister Base, flashing it, and printing it again. The design is then covered in a thinner printed layer of black-tinted Shatter Base. This too can be flashed and printed again to produce smooth, simulated-leather look. Minor modifications to dryer temperature and time spent curing can create a more textural, worn leather patch. You can even create a suede-like finish by experimenting with ink combinations and dryer settings.

Back to Top -

How much does custom screen printing cost?Your best bet is to visit our "Quick Quote" page and punch in all of your specifications and even upload some artwork. This is the fastest way to get the most accurate estimate. We work off of the quick quote's pricing matrix for all of our bidding. Pricing varies based on:

-Number of print colors on the front of the garment (more colors = more cost)

-Number of print colors on the back of the garment (more colors = more cost)

-Size of the print on the front of the garment (larger = more cost)

-Size of the print on the back of the garment (larger = more cost)

-Quantity of items ordered (the more you order, the less the price is per piece)

-What brand of blank garment you want us to use (hanes, gildan, etc.)

-What color the blank garment is (darker colors are more)

-Any other misc. specialty positioning and modifications to the shirt (these can be a bit more cost but add a lot of "kick" to the design!) Back to Top -

How much is custom design?We charge $45 per hour for custom graphic design. We make sure that our prices are fair for our clients. We work efficiently and keep strict time recording guidelines for all of our designers. Back to Top

-

How much is shipping?Shipping usually depends on where you are located but you don't have to worry about it because we will build it into the final piece price of your items! We currently only ship within the continental United States. Back to Top

-

Do I have to pay a sales tax?You only have to pay a 6% sales tax if you are located in the state of Idaho. Back to Top

-

What is the setup cost?That's one of the best parts about our prices...the setup cost is included! This way you can see exactly what you will be paying when you order your items. Back to Top

-

Where are you located?We have always avoided investing in a physical brick and mortar showroom/store due to high costs that are ultimately passed on to the customer. We find it much more efficient to operate online and offer unbridled customer service via e-mail, live chat, and telephone. The address of our manufacturing facility is:

Fastshion Inc.

2000 E. Dunwoody ct.

Meridian ID. 83646

We also operate sales offices in Boise Idaho.

If you ever have any other questions feel free to contact us! Back to Top -

How can I contact you guys?If you want the quickest response you can e-mail us at contact@fastshion.com Back to Top

-

Do you offer garment splattering?Yes we offer garment splattering. See our specialty services page to see an example. Back to Top

-

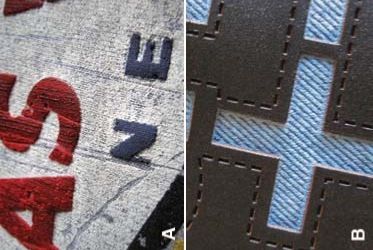

Do you offer full body printing?We currently offer full body printing in 1 color. Here is an example of full body printing.

Back to Top

Back to Top

-

What file formats should I use?

It is best for us to receive files in photoshop (.psd), illustrator (.eps or .ai), or CorelDraw (.cdr) format. We also have expert designers that can retouch designs and turn them into useable files. Many clients take advantage of this service if they only have access to .jpgs and .gif files. The standard fee for this is $35 per hour. This rate also applies for custom artwork design. Check out our slick portfolio to see what type of work we've done in the past for clients. If you have a .jpg or .gif with a resolution greater than 300dpi...we are often able to convert the artwork for free. Back to Top -

What is the turn around time?We guarantee the shipment of orders between 12-300 pieces within 24 hours of receiving the final order. :) Back to Top